Commanders!

Amongst the multitude of new trends and requirements swaying modern militaries and taking a firm hold is the one of electrifying things: almost no experimental technology these days can do without sticking a computer in it.

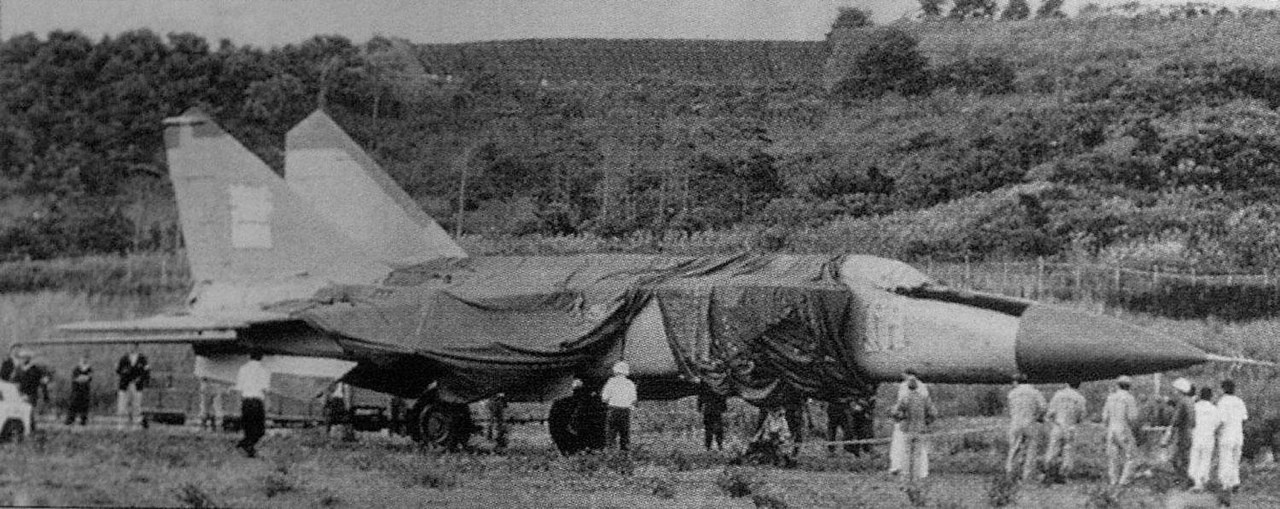

It seems logical – we are, after all, living in a digital age. Of course, solid state electronics are not always better, as the Americans found out in 1976, when they had the opportunity to dismantle the then cutting edge MiG-25 fighter jet, learning that many of its electronic parts were vacuum-tube-based, giving the fighter exceptional resistance to EM blasts caused by nuclear explosions.

Viktor Belenko's MiG-25P in Japan

Still, as the world becomes more connected and reaction times get faster, the computerization of military systems is all but unavoidable and the need for electricity grows ever higher. Subsequently, planning for a future war must take such requirements into account.

This isn’t a new issue by any means and increasing power consumption hounded both the soldiers and the logistics experts involved in the recent wars. For example, insufficient power capacity plagued the Bradley IFV during the Iraq war as well as in the other IED-ridden theaters of operation where consumption-heavy electronics such as jammers had to be deployed to keep the operators and the troops inside safe. The crew often had to switch off other components to make the jammer operational, which was less than ideal. In other words, it makes a lot of sense to significantly improve the power generation capacity of the next generation of fighting vehicles and, even now, we are also already seeing an increase in average APU capacity for most offered upgrades.

However, that is not all there is to the story, because the abovementioned electrification trend has another aspect – electric mobility (replacing standard combustion engine with a hybrid or an electric one). At first glance, this idea might seem ridiculous – how would one adapt a relatively new technology that’s being used in electric cars into a tank and why? Let’s take a look.

First of all, the electric car technology is not new. It’s very old – in fact, almost exactly as old as the combustion engine car. It made sense in a way – compared to a combustion engine, an electric motor is very simple in its basic design. We are talking, however, about the late 19th century – as you can imagine, the use of such cars was extremely limited and more of a curiosity than anything else. Electricity, however, made its way into mass transportation, mostly by the means of various combined drives such as the petro-electric and diesel-electric ones.

A diesel-electric system is quite simple. A diesel engine powers an electric generator, which in turn powers the electric motors that move the vehicle. Its main advantage is that it theoretically does not need a gearbox and a clutch, as electric motor revolutions per minute can be controlled by simply adjusting the power to them. The downside is the weight and size of this system, effectively restricting it to large platforms only such as marine ships and locomotives where it is used to this day.

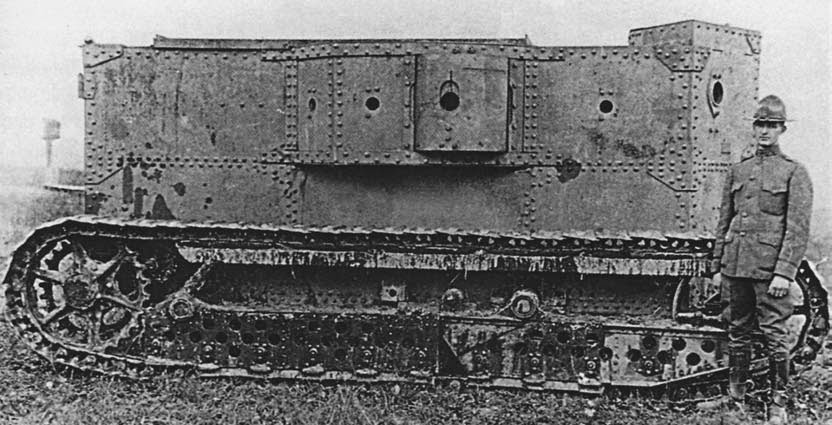

Holt Gas Electric Tank, 1917, USA

Naturally, the military, always aware of (or funding) new technologies, couldn’t stay away and the first attempts to use a petrol-electric or diesel-electric system appeared as early as in the First World War. Diesel-electric submarines became the gold standard of the branch until the appearance of nuclear propulsion due to the fact that while the diesel engine needed air to operate, the electric one did not and the submarine could therefore operate under water for a very limited time on batteries only.

On the ground, things were a lot more complicated. Some very early tanks during the WW1 period and even after the war were tested with this drive, but all of them generally suffered from serious reliability issues and the system was not deemed practical when compared to a more conventional engine, even though the potential ability to simply reversing the electric motor polarity in order to make one or both tracks move backwards would make for an excellent trait in a tracked vehicle, allowing it not only to turn on the spot (neutral steering), but also to retreat very fast.

The “golden age” of diesel-electric tanks (if it can be called that way) came during the Second World War with Ferdinand Porsche, who designed several vehicles with such a drive, including the mass-produced giant Ferdinand/Elefant tank destroyer and, of course, the mythical Maus super-tank. Long story short, it didn’t go well. The Elefant was notoriously unreliable, maintenance-heavy, fuel-hungry and – while becoming, much like the Tiger, one of the iconic and dreaded German vehicles of the Second World War – represented a developmental dead end. How such a platform became (relatively) mass-produced was more a matter of politics and Hitler’s admiration of Porsche than of common sense. The victors tested the Elefant platform and found it lacking – it never really went anywhere.

Ferdinand in Kubinka

For the remainder of the 20th century, electric mobility became practically restricted to small cities due to the high price and limited range of such vehicles. However, since the 2000s, a lot of money has been funneled into electric mobility research, partially out of its urban practicality, but mostly out of environmental concerns, be they rational or not. From pretty much any wide population point of view, full-scale implementation of electric mobility is an impractical thing that few want, and is pushed, especially in China and Europe, for other reasons.

But what about the military? Could they be interested in having electric armored vehicles?

The answer to this question is not simple and can be roughly summed up as “perhaps”. Private companies such as BAE are already working on or testing hybrid solutions for both the existing and future vehicles, but when the layers of corporate talk and buzzwords are peeled off, what remains is of little substance or improvement compared to the current generation of fossil fuel engines on its own. One has to look at the big picture to notice significant differences.

As far as individual vehicles are concerned, military electric motors, just like their civilian counterparts, offer:

- Better response

- Instant surge of power

- Potential ability to retreat very fast

- Improved acoustics

At the expense of potential range, costs, reliability and maintenance issues. As far as the advantages are concerned, have you ever attended a car event where a Tesla would out-accelerate pretty much every sports car? Same thing. Electric motors provide incredible amounts of instant power, which would, in tracked vehicles, translate into a major increase in agility and acceleration. Military technology in general is an extreme one, where, even now, peaks are required during combat at the expense of life-span. After all, what good is an engine that can last thousands of kilometers when the tank gets knocked out after a few minutes in combat? Agility and power are always good to have in battle – the more, the better.

Hybrid drive combat vehicle by BAE

The other advantages, however, are not as major as it might seem. The ability to drive very fast in reverse is not very practical due to the fact the driver often doesn’t really see to the back of the vehicle. Cameras are well and good, but you can’t seriously expect to drive a 50 ton tank like that for any significant period of time – such an action would be extremely dangerous to the crew, the vehicle and, most importantly, to its surroundings.

As for the improved acoustics part, it simply means that a vehicle running on electricity is quiet. This is actually a considerable advantage for various lighter wheeled vehicles tasked with scouting duties and the U.S. Army has already experimented with such a hybrid drive. On the other hand, heavier tracked vehicles such as tanks or IFVs practically negate this advantage due to the other sounds that they produce (the clanking of tracks is a VERY distinctive sound that can be heard at long distances) as well as the dust they kick up and their heat signatures. There are various means of reducing those as well (such as heat-masking camouflages or sound mufflers) but it doesn’t change the fact that such vehicles are inherently not stealthy.

Then there are the disadvantages.

The first and the most obvious one is, of course, the potentially limited range, although this is not as big a problem as one might think – at least not for IFVs and tanks. We are talking about 30 to 50 ton vehicles after all. Adding a few tons of batteries is a problem for a normal car, but for a tank? Not all that much. Here’s, however, where things go sideways.

Modern lithium-ion battery capacity lies somewhere in the region of 250-300 Wh/kg. Now, let’s take a modern 30 ton fighting vehicle as an example. Let’s say it has an engine with a consumption of 300 kW. Let’s also assume we want the same range as the Bradley IFV has – approximately 400km – and that the average speed of such a vehicle is 50 km/h. In other words, it needs 8 hours to reach it, which means supplying it with 300 kW for 8 hours – ergo, 2400 kWh.

BAE "Thor" hybrid drive demonstrator

Using the 300 Wh/kg value, such battery would have to weigh whopping 8 tons. That’s a lot and it will get only bigger with the power consumption of 1500hp tank class engines. Those of you who follow general AFV news know of the trend to develop new light armor with the same protection levels as the old one rather than adding more and more composite plates to MBTs. Adding a giant heavy battery to a tank that is already deemed to be too heavy doesn’t really help in this regard.

In comparison, the Bradley (with its old Cummins engine) carries around 700 liters of diesel fuel, which translates to roughly 600kg.

And, of course, there’s the matter of where would you even put such a battery. You can’t just replace the vehicle’s fuel tanks, they are much smaller. Combat vehicles are generally size-restricted in order to comply with the available means of transportation. One does not simply make them bigger. As a result, there would most likely be less space inside than there currently is. There are further negative implications of having battery-powered vehicles, but this suffices as an example.

Which brings us to the second problem – how does one charge such massive batteries. Aside from being slow to charge (an average 22kW car charger would take several days to charge the abovementioned 8-ton battery with the top of the line military chargers reaching the power of 350 kW), there is obviously the matter of producing enough power to charge anything (aside from powering the military base itself, of course).

Electric infrastructure is notoriously vulnerable or – in such places as Afghanistan – lacking altogether, so all the required power would have to be generated by the military and pretty much the only viable way to do so in large quantities would be to use diesel generators. That in turn means that the often cited advantage of electric vehicles in the military – that no fuel would have to be hauled around – is mostly illusory. That is not to say that fuel costs aren’t a problem. In Afghanistan, around 50 percent of the entire military transportation capacity was taken by fuel transports and given the dangers of attacks and the required transport protection, the cost of a single liter of military JP-8 fuel rose to 85 USD.

So would it really save some fuel transportation?

The fuel economy of a Bradley is approximately 1.7 miles per gallon, which translates roughly into 140 liters of fuel per 100km. For 400km, the vehicle would therefore consume on average some 560 liters of fuel. The U.S. Army currently uses a wide range of diesel generators, including a 200kW one by GMG – let’s assume that the abovementioned hypothetical IFV, requiring 2400 kWh to move the same distance, would be getting charged with a 200 kW charger, which translates into 12 hours of charging (ignoring all system losses for the sake of the example).

M2A3 Bradley

The full load 200kW generator consumption is roughly 50 liters of fuel per hour. Charging the vehicle in this configuration would therefore require 600 liters of fuel, which is more than a Bradley would consume on its own. In reality, if an infrastructure with large generators was built, it would obviously be less, but fuel costs would still be an issue.

There are other considerations as well. You can pour some fuel into a can, but electrical energy cannot be easily transported. At these power levels, maintenance and repairs of such systems are no joke and cannot be handled in the field – they also require specialists and equipment to do so.

Batteries also require some elements such as lithium and cobalt, which are not only finite, but also difficult to produce. Cobalt is especially problematic with most of it being mined in a rather turbulent area of the world (Democratic Republic of the Congo), which isn’t exactly good for the strategic needs of western militaries.

Furthermore, the development and procurement costs of such a technology would also be extremely high and even though the advanced militaries across the world are used to the taxpayer footing pretty much any bill, it would be incredibly tough for any politician to sell such a program to his or her constituents.

And yet, it seems that this is already happening. The American Department of Defense promised to use renewable sources for 25 percent of the energy it yearly consumes. This is quite a promise, considering that its energy bill costs about 20 billion USD each year and the electricity consumption alone equals that of one half of a smaller European country.

Akrep II, the first Turkish electric AFV

On the operational side of things, the U.S. military is talking about its electric future already with some of its representatives predicting that by the 2030s, some brigade combat teams will already be fully electric thanks to the adoption of a new generation of fighting vehicles, including the NGCV. This shift is mostly justified by the need to reduce the fuel consumption of the military with a single brigade combat team (roughly 4 thousand men strong) consuming as much as 7500 liters of fuel per operational day. While a large-scale deployment of such vehicles is unlikely for the near future, it seems that the future of the U.S. Army might be electric indeed. Whether the other countries will follow suit remains to be seen.

In Armored Warfare, you had the opportunity to drive an electric vehicle already. An experimental, hypothetical version of the Turkish Altay MBT was available as the main prize for the last Battle Path campaign, featuring – amongst other things – the unique sound of an electric drive. But those of you, who didn’t have or take the opportunity to receive it, worry not.

In the near future, another electric – or, specifically, hybrid – vehicle will appear in Armored Warfare. Stay tuned for more information to be revealed soon and as always:

See you on the battlefield!